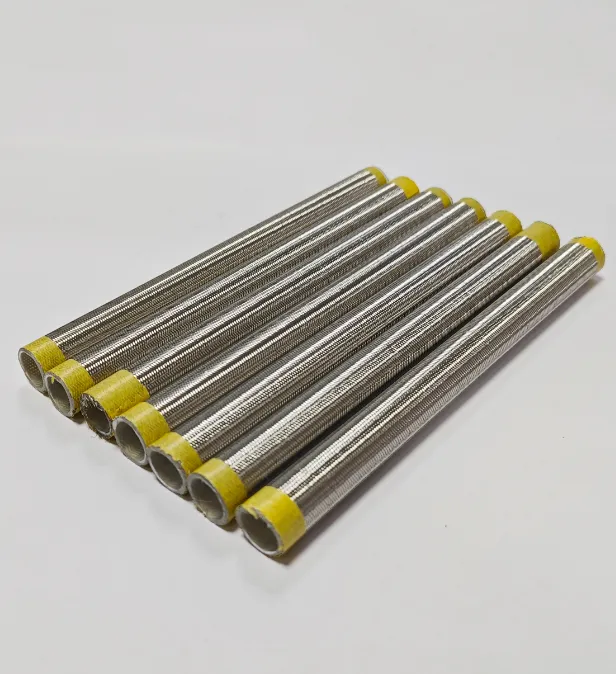

Our bending mesh is woven from highly elastic stainless steel wire, offering both durability and flexibility, making it ideal for medical endoscope repair. Customizable (wire diameters 0.1-0.3mm) and with an anti-oxidation coating option, our bending wire mesh is priced at only 30%-50% of the original price, making it an ideal alternative for repairers and OEMs.

| Brand | Model | Other | ||

| BMGNRALL 13.8 | Bending Mesh Ø 13.8MM | General | ALL | 13.8 |

| BMGNRALL 12.9 | Bending Mesh Ø 12.9mm | General | ALL | 12.9 |

| BMGNRALL 11.5 | Bending Mesh Ø 11.5mm | General | ALL | 11.5 |

| BMGNRALL 10.5 | Bending Mesh Ø 10.5mm | General | ALL | 10.5 |

| BMGNRALL 9.8 | Bending Mesh Ø 9.8mm | General | ALL | 9.8 |

| BMGNRALL 9.5 | Bending Mesh Ø 9.5mm | General | ALL | 9.5 |

| BMGNRALL 9.2 | Bending Mesh Ø 9.2mm | General | ALL | 9.2 |

| BMGNRALL8.5 | Bending Mesh Ø 8.5mm | General | ALL | 8.5 |

| BMGNRALL8.0 | Bending Mesh Ø 8.0mm | General | ALL | 8.0 |

| BMGNRALL7.5 | Bending Mesh Ø 7.5mm | General | ALL | 7.5 |

| BMGNRALL7.0 | Bending Mesh Ø 7.0mm | General | ALL | 7.0 |

| BMGNRALL6.5 | Bending Mesh Ø 6.5mm | General | ALL | 6.5 |

| BMGNRALL6.0 | Bending Mesh Ø 6.0mm | General | ALL | 6.0 |

High Corrosion Resistance: Our bending wire mesh is made of specialized 316L medical stainless steel or nickel-titanium alloy, maintaining stability in strong acid (pH < 2) and alkaline (pH > 12) environments, preventing brittle mesh fracture caused by chemical disinfectants.

Multi-layer Composite Coating: Our bending mesh can be custom plated with gold, nickel, or PTFE to reduce chemical penetration and maintain long‑term flexibility even in bio‑corrosive environments such as gastric acid and bile.To further ensure product integrity and leak resistance before assembly or clinical use, technicians may employ tools like a zutron leak tester to verify the mesh and related assemblies meet stringent sealing requirements.

Ultra-Abrasion-Resistant Structure: Optimized braid density (200-300 mesh) and cross-node reinforcement significantly reduce the risk of metal powder shedding caused by friction with endoscope sheaths.

High-Temperature Stability: These bending meshes withstand repeated 134°C autoclave sterilization or ethylene oxide sterilization without peeling or deformation, making them suitable for medical applications with stringent sterilization requirements. For facilities that prioritize rigorous quality control during endoscope maintenance and repair, tools like an Olympus scope leak tester are often used to verify sealing and identify early‑stage defects before clinical reuse.

Industrial-grade environment adaptability: For industrial scenarios such as oil and gas pipeline inspection, an additional silicon carbide wear-resistant coating can be added to withstand harsh chemical environments such as H₂S and salt spray, extending the service life by more than 3 times.

Factory-grade service, like-new.

As a professional endoscopy repair company, our repair technicians are all experienced technicians with 10 years of experience. Every bending wire mesh replacement is calibrated to the original factory specifications, ensuring smooth installation and bending performance, just like a new mirror.

Using premium materials for a longer lifespan.

We use imported 316L medical steel bending mesh, which is extremely durable and can withstand exposure to acids and alkalis. It can be bent tens of thousands of times without deformation, lasting at least two years longer than standard products.

Transparent pricing, no hidden tricks.

Before replacing the bending wire mesh, we'll clearly explain the problem, price, and warranty. We never charge extra fees mid-repair. If any issues arise within three months after the replacement, you can contact us for rework at any time.

Fast repairs, worry-free worldwide.

Express international shipments are shipped within 72 hours, and we support direct shipping via DHL/UPS, ensuring you're ready to use right away.