Tel: +86-19906868508

E-mail: info@sihanmed.com

Tel: +86-19906868508

E-mail: info@sihanmed.com

Few things are more frustrating than a stuck bending section mid-procedure—like a dancer with two left feet, your scope suddenly refuses to move smoothly. Whether you’re battling stiff steering, unpredictable angulation, or outright mesh breakage, the culprit is often the same: preventable wear and tear.

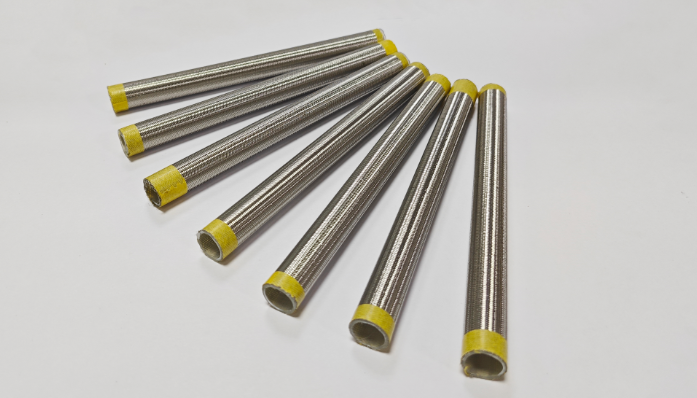

The most common causes of bending mesh failure are excessive force, improper cleaning, and fatigue from high-frequency use. Prevent damage by avoiding aggressive maneuvering, using enzymatic cleaners (no abrasives!), and scheduling regular professional maintenance before small issues escalate.

Now, let’s dissect why your endoscope’s most flexible friend sometimes turns into its stiffest enemy—and how to keep it bending without breaking.

Ever watched a colleague wrestle a scope like it owes them money? Therein lies the first sin. The bending section, though resilient, isn’t designed for heroic torque—especially when navigating tricky anatomy. Repeated forced deflection stresses the bending welded wire mesh, causing micro-fractures that worsen with time.

Ironically, newer scopes suffer more here. Their ultra-responsive controls tempt users to push limits, accelerating wear. The fix? Train staff to feel resistance and retreat, not ram through. Better three gentle adjustments than one brute-force bend. And if your scope groans audibly, it’s begging for mercy.

Think your endoscope’s worst enemy is biofilm? Think again. Harsh cleaners—particularly chlorine-based or high-pH solutions—corrode the bending wire mesh’s stainless steel strands, turning them brittle. Even proper agents, if improperly diluted or overused, chip away at the protective oxide layer.

Enzymatic cleaners are the safe bet, dissolving debris without attacking metal. And never, ever soak the bending section longer than recommended—corrosion works its mischief silently. A scope cleaned wrong is like a sword left in the rain: it might look fine… until it snaps.

There’s no avoiding physics. Every bend weakens the mesh slightly, and high-volume clinics face this sooner. Worse, fatigue damage is cumulative—small stresses add up until, without warning, a wire gives way.

Red flags include erratic bending angles or a "notchy" feel. Catching these early lets you reinforce or re-stitch the mesh before catastrophic failure. Pro tip: Rotate scopes in heavy-use settings to distribute wear.

| Mistake | Why It’s Bad | Better Practice |

|---|---|---|

| Coiled too tightly | Creates permanent stress points | Store in relaxed loops |

| Hung by the insertion tube | Weight strains bending section | Use a support strap near the control unit |

| Left in a humid environment | Moisture accelerates rust | Store vertically in a dry cabinet |

Neglecting these "small" habits guarantees premature breakdowns. A scope tossed in a drawer is like a marathon runner left in high heels—functional, but not for long.

Replacing a single wire yourself? Tempting, but doomed. Mesh strands must align perfectly; makeshift fixes alter tension across the entire section, hastening future failures.

Generic mesh might fit… briefly. Inferior alloys corrode faster or lack flexibility. OEM or surgical-grade steel is non-negotiable.

A mesh failure often masks deeper issues—misaligned pull wires, fractured sheaths. True repair requires full diagnostics, not just swapping visible parts.

Final Thought: The bending section doesn’t fail—it’s failed by misuse. Treat it right, and it’ll flex reliably for years; neglect it, and prepare for costly downtime.

With years of dedication to the medical equipment industry, Shengjun He has leveraged his solid professional expertise and keen insight into industry trends to establish Sihan Medical as a leading force in the endoscope repair sector. Prior to founding Sihan Medical, he accumulated extensive experience in medical device maintenance—a foundation that proved instrumental for his entrepreneurial journey. His background spans hands-on equipment repair, technical R&D, and management, granting him comprehensive understanding of medical devices, from their underlying technology to market demands.